Produkt oversigt

Produkt Specifikationer

| INGEN. | detaljer | Original Manufacturer | Mærke navn |

| 1 | NC system | Holland | DELEM DA-53 series(Matching) |

| Switzerland | CYBELEC CT8(Standard) | ||

| 2 | Sealed linear encoder | Turkey | OPKON |

| 3 | Hydraulisk system | German | REXROTH/ ARGOS-HYTOS |

| 4 | Olie pumpe | America/Japan | SUNNY/ NACHI |

| 5 | Kugleskrue | Taiwan | HIWIN/ PMI |

| 6 | Straight guide rail | Taiwan | HIWIN/ PMI |

| 7 | Seal | Japan | Japan NOK |

| 8 | Air switch | France | Schneider |

| 9 | Miniature relay | France | Schneider |

| 10 | Ac contactor | France | Schneider |

| 11 | Button | France | Schneider |

| 12 | Elektriske komponenter | Japan | Omron |

| 13 | Socket joint | USA | EATON |

| Technical Parameters & Specification with 130 Ton | |||

| Workbench length | 3200 | mm | |

| Afstand mellem søjler | 2700 | mm | |

| Skyderslag | 200/250 | mm | |

| Åben højde | 450/500 | mm | |

| Halsdybde | 400 | mm | |

| Axis number of NC | Y1、Y2、X、R、V | axes | |

| Hovedmotoreffekt | 11 | kw | |

| Slidehastighed | Fast down | 180 | mm |

| Work | 10 | mm | |

| Vend tilbage | 160 | mm | |

| Back gauge X axis | Slag | 600 | mm |

| Max speed | 350 | mm/s | |

| Re-position accuracy | ≤0.05 | mm | |

| Back gauge R axis | Slag | 200 | mm |

| Max speed | 200 | mm/s | |

| Re-position accuracy | ≤0.05 | mm | |

| Machine Dimensions | Længde | 3800 | mm |

| Bredde | 1850 | mm | |

| Højde | 2750 | mm | |

| Maskinens vægt | / | 9000 | kg |

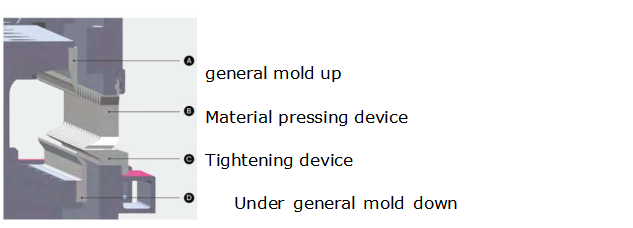

Produktkonfiguration

Moving front support frame: It moves along the linear guide rail and can be parked at any position to assist your bending work and make the work comfortable and efficient.

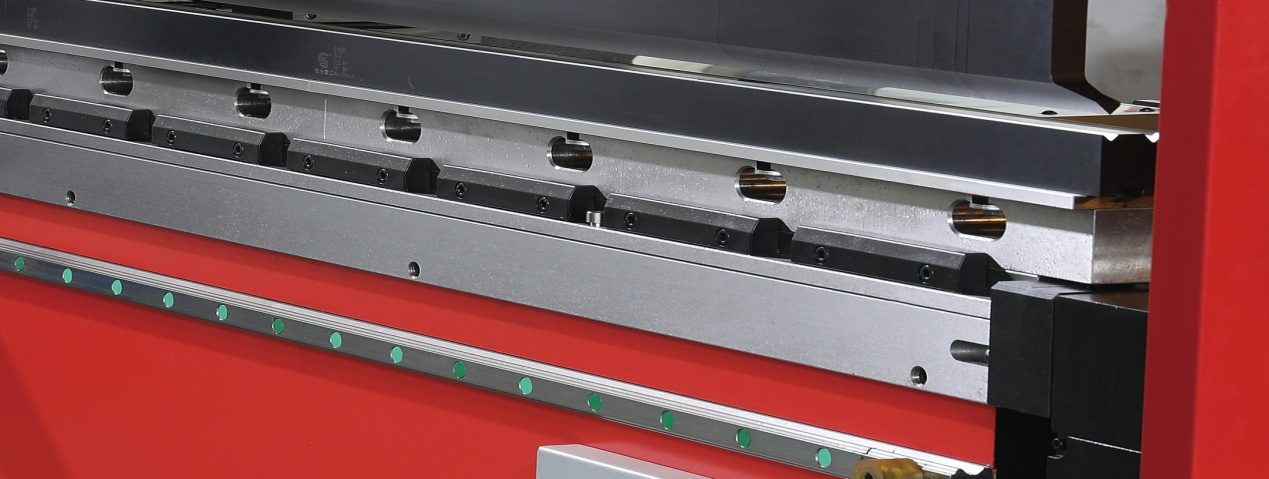

High Precision and fast clamping system: fast and easy to change the tooling, decreasing labour strength and enhance productivity.

Higher quality press brake tooling:whole hardened high precision CNC press brake tooling it is durable.

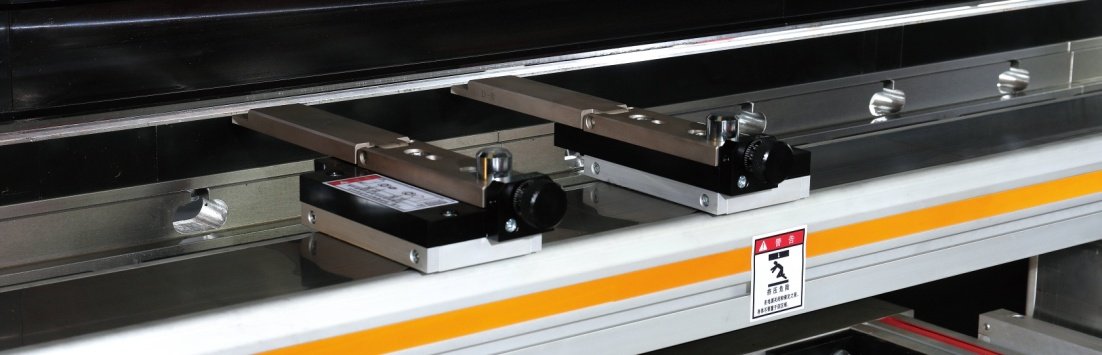

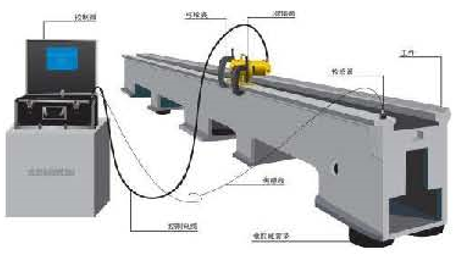

High precision and stable back gauge system(Optional): New and unique double linear guide constrction,To ensure the good positioning accuracy.Design of multistage stops, to increase the positioning range, above the price in value.

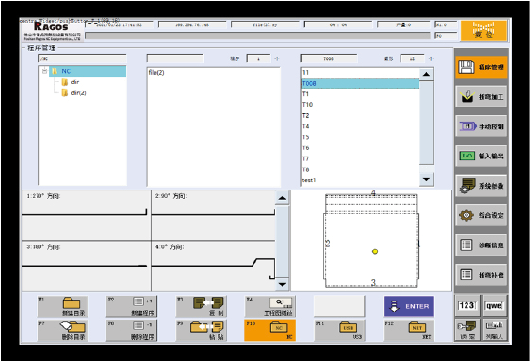

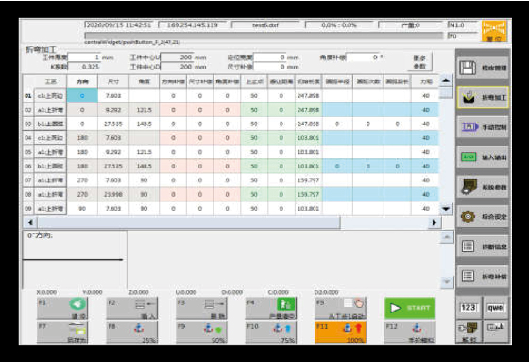

Easy to operate cnc control system can help you save time to improve working efficiency.

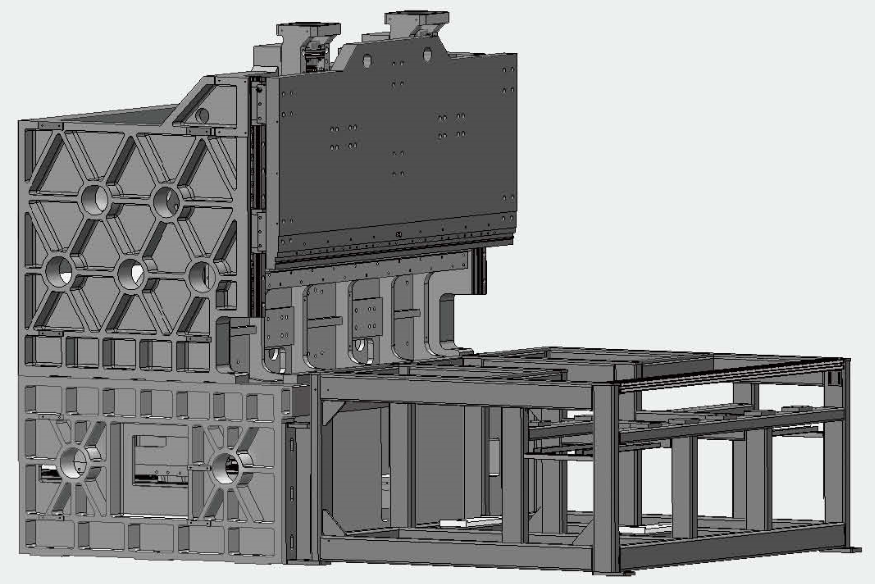

Cast machine body (featuring stable structure, small deformation and high precision

Machine tool technology

Vibration aging stress relief

Vibration aging stress relief

To eliminate the internal stress of workpiece, ensure that the machine works for a long time with high precision.

Finished machining

Finished machining: Owned large horizontal gantry milling machines for meeting Ragos precise machining requirements, also ensure high quality installation base.

Natural aging: Machine frames need to be placed naturally for 6 months to release stress from heat treatment, which is to get stable accuracy and higher rigidity.

Below is the machine bedding processing

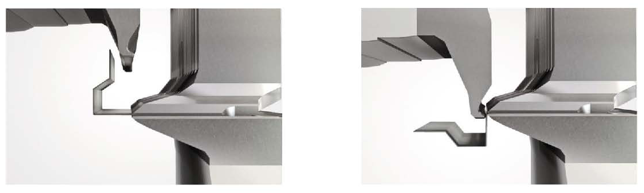

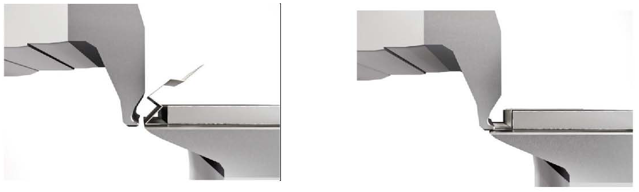

Bend Up

Bend Down

Flattening and bending

Sheet positioning system

Tail positioning Plate pre-positioning Final positioning

Product samples

detaljer

- Slider Stroke (mm): 300 mm

- Automatisk niveau: Fuldautomatisk

- Halsdybde (mm): 400 mm

- Maskintype: Torsion Bar

- Arbejdsbords længde (mm): 4000

- Arbejdsbords bredde (mm): 2500 mm

- Dimension: 4000*2500*3600

- Tilstand: Ny

- Materiale/metalforarbejdet: Rustfrit stål, LEGERING, Kulstofstål, Aluminium

- Vægt (KG): 7000

- Motor Power (kw): 25 kw

- Nøgle salgsargumenter: Højt sikkerhedsniveau

- Garanti: 1 år

- Applicable Industries: Machinery Repair Shops, Manufacturing Plant, Home Use, Construction works , Advertising Company

- Udstillingslokale: Ingen

- Marketingtype: Nyt produkt 2020

- Maskintestrapport: Leveres

- Video udgående inspektion: Forudsat

- Garanti på kernekomponenter: 1 år

- Core Components: Bearing, Motor, Gear, Engine

- Produktnavn: Hydraulisk Cnc Bukkemaskine

- Råmateriale: Ark

- Power: 7.5kw 10kw 15kw 20kw

- Anvendelse: Rustfri pladebøjning

- Funktion: Stål Metal bøjning

- Control system: DA69T-DA66T-DA58T-CT8-CT12

- CNC System: Delem Holland

- Hydrauliksystem: Bosch Rexroth Tyskland

- Color: White and red

- Hovedmotor: Siemens Tyskland

- Eftersalgsservice: Gratis reservedele, Feltinstallation, idriftsættelse og træning, Feltvedligeholdelse og reparationsservice, Videoteknisk support

- Efter garantiservice: Video teknisk support, online support